home Sintered Wire Mesh Filter

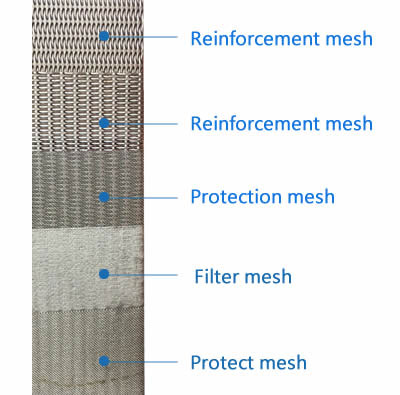

Sintered wire mesh is made form multiple layers of woven wire mesh panel together using a sintering process. This process combines heat and pressure to permanently bond multi-layers of mesh together. The same physical process used to fuse individual wires together within a layer of wire mesh is also be used to fuse adjacent layers of mesh together. This creates a unique material offering excellent mechanical properties. It is ideal material for purification and filtration. It may be from 5, 6 or 7 layers of wire mesh (5 layers sintered filter mesh structure drawing as right picture).

The follow picture shows a sintered stainless steel wire mesh panel made form five different layers of stainless steel wire mesh combined and sintered together through vacuum sintering, compressing, and rolling, forming a porous sinter mesh.

Our sintered mesh panels may be formed into filter elements such as filter discs, cartridges, cones, cylinders, and tube.

Send Enquiry Download PDF

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particle, transpiration cooling under extremity high temperature, control air flow distribution, enhancement of heat and mass transfer, noise reduction, current limitation, and wildly used in aerospace, petrochemical industry, pharmaceutical industry, environmental protection industry.

The RD range of filter cartridges and elements are constructed in stainless steel 316L as standard. These filters are available in a pleated cartridge configuration, giving 0.13m2 (1.40ft2) of active filtration area per 10" length.

This pleated cartridge design uses a precision pleated pack, comprising of protection and support meshes either side of the filter medium, around a support core to provide nearly three times the effective filtration area of the cylindrical element.

The filter media and support meshes are either plasma or TiG seam welded and the media support core and end fittings are fully TiG welded together. This method of construction guarantees cartridge integrity, eliminating the risk of bypassing and the presence of extractables derived from bonding agents.

The method of construction and materials used allow for operation from -269oC (-452oF) to 1000oC (1832oF) and up to 25bar (363psi) differential pressure in normal flow direction. Higher operating temperatures and differential pressures can be accommodated by design.

In the double open ended configuration, in addition to the support core, there is a 25mm (1") inner core to assist the location of multiple length units onto tie rods. Our pleated cartridges are supplied with a guard as standard for backflow/backflushing protection up to 3bar (44psi) differential.

316L stainless steel standard. Inconel®, Hastelloy®, NiCrMo Alloy 59 and Fecralloy® on request or by process selection. Additional alloys are available on request.

Diameter: 66mm (2.6") as standard.Lengths: 125mm (5"), 250mm (10"), 498mm (20"), 745mm (30") and 1012mm (40"). * Other diameters and lengths available on request.

0.13m2 (1.40ft2) per 250mm (10") cartridge.

EPDM as standard. Nitrile, PTFE, Silicone, Viton® and PTFE coated Viton® available on request or by process selection. * FDA approved seals are available.

Normal flow direction: 25bar (363psi)Reverse flow direction: 3bar (44psi).

Maximum continuous: From -195oC (-319oF) to 340oC (644oF) seal limiting.From -269oC (-452oF) to 1000oC (1832oF) alloy limiting.

Send Enquiry